How Do I Troubleshoot Common Problems With Steamers?

If you’ve ever found yourself grappling with common issues when using steamers, you’re not alone. From stubborn wrinkles to faulty water tanks, troubleshooting these problems can seem daunting. But fear not – this article is here to help you sail smoothly through the world of steamers. Whether you’re a seasoned pro or a newbie, we’ve got you covered with practical tips and tricks to overcome these pesky obstacles and get your clothes looking fresh and wrinkle-free in no time. So, sit back, relax, and let’s troubleshoot your steamer problems together!

Understanding the Basics of Steamers

If you own a steamer or are considering purchasing one, it’s essential to understand the basics. Steamers are versatile appliances used to remove wrinkles from clothing, freshen fabrics, and even sanitize household surfaces. There are different types of steamers available on the market, each with its unique features and benefits.

Types of Steamers

-

Handheld Steamers: These compact steamers are portable and convenient for quick touch-ups and travel. They are great for removing wrinkles from delicate fabrics, such as silk or linen.

-

Garment Steamers: Also known as clothes steamers, these models are larger than handheld steamers and are designed specifically for steaming garments. They often come with a hanger and a nozzle that delivers a powerful steam flow.

-

Steam Mops: These steamers are designed for cleaning and sanitizing floors. They come with a mop head that releases steam to blast away dirt and grime, leaving your floors fresh and germ-free.

-

Steam Cleaners: These multifunctional steamers can be used for various tasks, including steaming clothes, cleaning upholstery, sanitizing surfaces, and even removing wallpaper. They have a greater capacity and power compared to other steamers.

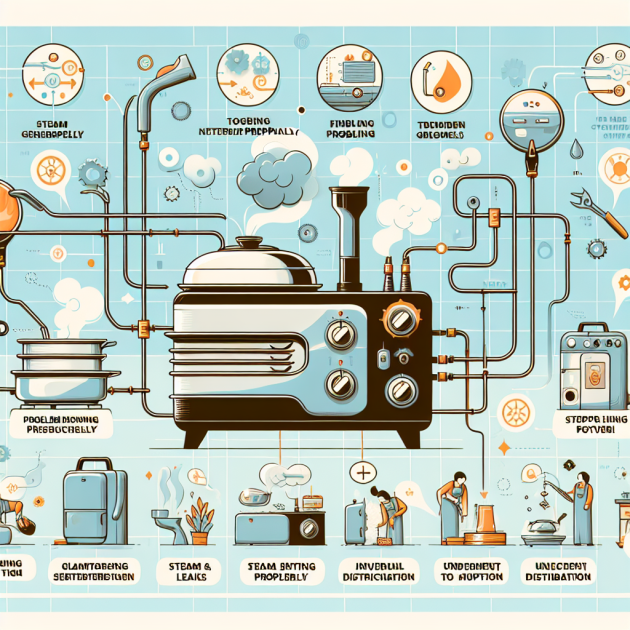

Basic Functions of a Steamer

Regardless of the type of steamer you’re using, the basic function remains the same. Steamers convert water into steam, which is then used to remove wrinkles and freshen fabrics. The steam is produced by heating the water inside the steamer, and it is delivered through a nozzle or a steam head.

Steamers generally offer adjustable steam settings, allowing you to control the intensity of the steam flow depending on the fabric you’re working with. This feature ensures that you can safely steam delicate fabrics without the risk of damage.

Safety Measures When Using a Steamer

While steamers are generally safe to use, it’s crucial to follow some safety measures to avoid accidents or injuries. Here are a few tips to keep in mind:

-

Read the user manual: Before using your steamer for the first time, make sure to familiarize yourself with the manufacturer’s instructions and guidelines. This will ensure that you understand how to operate the steamer safely.

-

Handle with care: When using a handheld steamer or a steam mop, be cautious with the hot steam and the heated surfaces. Avoid pointing the steam nozzle towards yourself or anyone else.

-

Use distilled water: To prevent mineral build-up and extend the lifespan of your steamer, it’s recommended to use distilled or demineralized water. Tap water may contain minerals and impurities that can clog the steamer’s internal components over time.

-

Maintain a safe distance: When steaming garments, keep a safe distance between the steamer’s nozzle and the fabric. This will prevent any accidental burns or scorching.

-

Unplug when not in use: Always unplug the steamer from the power source after each use and allow it to cool down completely before storing it.

Now that you have a good understanding of the basics of steamers, let’s move on to troubleshooting common problems that you may encounter.

Identifying Common Problems with Steamers

While steamers can be incredibly useful, they are not entirely immune to technical issues. Understanding the common problems associated with steamers will help you troubleshoot and fix them promptly. Here are some common issues you might encounter:

1. Ineffectiveness in Steaming

One of the most common problems with steamers is when they fail to produce adequate steam or when the steam loses its power. This can be frustrating, especially when you’re trying to remove wrinkles from clothes or sanitize surfaces.

2. Difficulty Turning On

If your steamer is not turning on when you try to use it, there might be an underlying issue preventing it from powering up. This can be due to a problem with the power source, a malfunctioning switch, or damaged wiring.

3. Excessive Noise Production

Steamers typically produce a certain level of noise during operation. However, if you notice an unusually loud or excessive noise coming from your steamer, there may be an issue that requires attention.

4. Water Leakage

Water leakage is another common problem that steamers can experience. If you notice water dripping or puddling around the steamer, it’s important to address this issue promptly to avoid any damage to the appliance or surrounding surfaces.

5. Overheating

Steamers are designed to operate at high temperatures to generate steam. However, if your steamer is overheating or becoming too hot to handle, it can be a safety concern and may indicate an underlying issue.

6. Faulty Fill Indicator

The fill indicator on your steamer is essential for monitoring the water level. If it malfunctions or fails to provide accurate readings, it can make it challenging to determine when it’s time to refill the water reservoir.

Now that we’ve identified the common problems, let’s explore possible troubleshooting techniques for each issue.

Troubleshooting Ineffective Steaming

Possible Causes of Ineffective Steaming

Several factors can contribute to ineffective steaming. One possible cause is a low water level in the reservoir. If there’s not enough water, the steamer may not produce sufficient steam to effectively remove wrinkles. Other potential causes can include mineral build-up within the steamer’s components or a faulty heating element.

Checking the Water Level

First, check the water level in the steamer’s reservoir. Ensure that there is an adequate amount of water to generate steam. If the water level is low, refill the reservoir according to the manufacturer’s guidelines.

Inspecting the Steaming Vents

Next, inspect the steaming vents for any blockages. Over time, mineral deposits or debris can accumulate in the vents, hindering the steam flow. Clean the vents using a soft-bristle brush or a cotton swab to remove any obstructions gently.

Testing the Heating Element

If the water level is sufficient and the vents are clear, the heating element might be the issue. Testing the heating element requires caution and technical expertise. It’s recommended to consult a professional if you suspect a faulty heating element.

By addressing these troubleshooting steps, you should be able to resolve ineffective steaming issues with your steamer.

Fixing Steamers That Won’t Turn On

Checking the Power Source

When your steamer fails to turn on, the first step is to check the power source. Ensure that the steamer is plugged into a working electrical outlet. If it is, try plugging a different device into the same outlet to determine if the issue lies with the outlet or the steamer itself.

Ensuring the Switch is Functioning

Next, make sure that the power switch on the steamer is in the “on” position. Sometimes, the switch may become loose or get stuck, preventing the steamer from turning on. Gently toggle the switch back and forth a few times to ensure it is functioning correctly.

Inspecting for Wire Damages

Check the power cord and the entire length of the wire for any visible damages or frayed areas. If you notice any cuts or exposed wires, it’s important to discontinue use and have the cord replaced or repaired by a professional.

Resetting the Steamer

If all else fails, try resetting the steamer. Some steamers have a reset button or a thermal overload switch that may have been triggered due to overheating or electrical issues. Refer to the user manual to locate the reset button, if applicable, and follow the instructions to reset the steamer.

By following these troubleshooting steps, you should be able to resolve the issue of a steamer that won’t turn on.

Dealing with Excessive Noise in Steamers

Reasons for Noise Production

Excessive noise coming from a steamer during operation can be caused by several factors. One common reason is the presence of scale or mineral build-up within the steamer’s components. Another potential cause can be loose parts or inadequate maintenance.

Checking for Scale Build-up

Scale build-up occurs when minerals in the water accumulate inside the steamer’s heating element or other parts. This build-up can restrict the flow of steam and cause the steamer to make unusual noises. Descaling the steamer regularly with a descaling solution recommended by the manufacturer can help reduce scale build-up and minimize noise.

Securing Loose Parts

Inspect your steamer for any loose or rattling parts. Over time, vibrations during operation can cause nuts, bolts, or screws to become loose. Use a screwdriver or the appropriate tool to tighten any loose components, taking care not to overtighten.

Verifying the Pump Functionality

Some steamers, particularly steam mops and handheld models with continuous steam flow, may have a pump responsible for circulating the water and generating steam. If the pump isn’t functioning correctly, it can create noise. Refer to the user manual to understand how the pump should operate and check for any issues, such as clogs or a malfunctioning pump motor.

By addressing these potential causes, you can reduce excessive noise in your steamer and enjoy a quieter steaming experience.

Addressing Water Leakage in Steamers

Finding the Source of Leakage

When dealing with water leakage, the first step is to identify the source of the problem. Thoroughly inspect your steamer and look for any visible signs of water leakage. Pay attention to the water reservoir, hose connections, and any seals or gaskets that may be damaged.

Examining the Hose for Damage

Check the hose for any cracks, holes, or loose connections. Even a small pinhole or loose fitting can cause water to leak out. If you notice any damage, you may need to replace the hose or tighten the connections securely.

Sealing Loose Connections

If the leakage is occurring at a connection point, such as where the hose attaches to the steamer or the nozzle, ensure that the connections are tightly secured. Use an adjustable wrench or pliers to tighten the fittings without overtightening.

Replacing Worn-Out Seals

Over time, seals and gaskets within the steamer can deteriorate, resulting in water leakage. If you suspect a faulty seal, consult the user manual or contact the manufacturer to obtain the correct replacement seals. Follow the manufacturer’s instructions to replace the seals properly.

By taking these steps, you can effectively address water leakage issues in your steamer and prevent further damage.

Managing Overheating Issues in Steamers

Common Causes for Overheating

Several factors can contribute to overheating in steamers. One possible cause is a malfunctioning thermostat that fails to regulate the temperature properly. Additionally, an inadequate water supply, blocked steam vents, or a damaged heating element can also lead to overheating.

Checking the Thermostat

Check the thermostat on your steamer to ensure it is functioning correctly. If the thermostat is faulty, it may not shut off the heating element when the desired temperature is reached, leading to overheating. If you suspect a thermostat issue, it’s best to consult a professional to replace or repair it.

Ensuring Adequate Water Supply

Insufficient water in the reservoir can cause the heating element to overheat. Make sure the water level is within the recommended range before operating the steamer. Refill the reservoir if necessary, following the manufacturer’s guidelines.

Cleaning Blocked Steam Vents

Blockages in the steam vents can prevent proper ventilation, leading to overheating. Inspect the vents for any obstructions, such as mineral deposits, lint, or debris. Use a soft brush or a cotton swab to gently clean the vents and ensure they are clear and free from any blockages.

By addressing these potential causes of overheating, you can effectively manage the issue and prevent any potential safety hazards.

Rectifying Faulty Fill Indicator Issues

Recognizing Indicator Malfunctions

A faulty or malfunctioning fill indicator can make it difficult to monitor the water level in your steamer accurately. This can lead to either overfilling the reservoir or running the steamer on low water, both of which can cause damage to the appliance.

Check the Water Level Sensor

Inspect the water level sensor, typically located inside the water reservoir or near the fill indicator. Make sure it is clean and free from any debris that may hinder its functionality. Gently wipe the sensor with a soft cloth or cotton swab to remove any dirt or residue.

Cleaning the Indicator Lens

Sometimes, a dirty or foggy indicator lens can make it challenging to read the water level correctly. Clean the indicator lens using a mild glass cleaner or a damp cloth to ensure clear visibility of the fill indicator markings.

Replacing a Broken Indicator

If none of the above troubleshooting steps resolves the issue, the fill indicator itself may be faulty. Refer to the user manual or contact the manufacturer to see if a replacement fill indicator is available. Follow the manufacturer’s instructions to replace the indicator correctly.

By rectifying faulty fill indicator issues, you can ensure accurate monitoring of the water level in your steamer, preventing any unnecessary damage or malfunctions.

Maintaining Your Steamer for Longer Life

To ensure that your steamer functions optimally and lasts for an extended period, regular maintenance is essential. Here are some maintenance practices to consider:

Regular Cleaning Regime

Cleaning your steamer after each use is crucial to remove any mineral deposits or debris that can accumulate over time. Follow the manufacturer’s instructions to clean the various components of your steamer thoroughly.

Descaling the Unit

Regular descaling is essential to prevent mineral build-up in your steamer. Use a descaling solution recommended by the manufacturer and follow the instructions provided. Regular descaling will help maintain the efficiency and performance of your steamer.

Proper Storage Practices

When storing your steamer, ensure that it is completely dry and cooled down. Store it in a cool, dry place away from direct sunlight or extreme temperatures. Also, consider using the original packaging or a dust cover to protect it from dust and debris.

Replacing Parts Timely

If you notice any worn-out or damaged parts, such as hoses, seals, or filters, replace them promptly. Regularly inspect your steamer for any signs of wear and tear to ensure its optimal performance.

By implementing these maintenance practices, you can prolong the lifespan of your steamer and enjoy its benefits for years to come.

When to Seek Professional Help

While many steamers’ issues can be resolved with DIY troubleshooting, some problems may require professional intervention. Here are some instances when it’s best to seek professional help:

Recognizing Beyond DIY Repair

If despite your best efforts, you are unable to resolve the issue or pinpoint the cause of the problem, it’s time to consult a professional. They have the expertise and knowledge to diagnose and fix complex steamer issues.

Finding a Trusted Repairman

When seeking professional help, it’s essential to find a trusted and qualified repairman. Ask for recommendations from friends or family, or check online reviews to ensure that you choose a reputable repair service.

Cost-Benefit Analysis of Repair vs. Replacement

Consider the cost of repairing your steamer versus the price of purchasing a new one. If the repair costs are significantly high and your steamer is obsolete or outdated, it may be more cost-effective to replace it with a new model.

Safety Aspects of Professional Repair

If you suspect that the issue with your steamer poses a safety risk or if there’s a potential for electrical hazards, it’s crucial to prioritize your safety and let a professional handle the repair.

By knowing when to seek professional help, you can ensure that your steamer is restored to proper working condition efficiently and safely.

In conclusion, understanding the basics of steamers is essential for using, troubleshooting, and maintaining these appliances effectively. By knowing the different types of steamers, their basic functions, and the necessary safety measures, you can ensure optimal performance and longevity. Identifying and troubleshooting common problems such as ineffective steaming, difficulty turning on, excessive noise production, water leakage, overheating, and faulty fill indicators can help you address these issues promptly. By following proper maintenance practices, you can extend the life of your steamer and enjoy its benefits for years to come. And finally, knowing when to seek professional help ensures that any complex or safety-related issues are resolved by qualified experts. So, go ahead and make the most of your steamer, wrinkle-free clothing, sanitization, and a cleaner home await you!